For example two separate pressure ports are compared and the difference between them is noted. Heat transfer equipment may be designated by type or function it performs such as chiller condenser cooler reboiler etc.

What Is Differential Pressure In A Heat Exchanger A Michigan Machinist Explains Mid West Instrument

Background history points out this exchanger have always been hydro tested thru differential hydro test.

. Pump shut-off head can be calculated as Maximum suction pressure 125 x. A followup arti-cle on advanced topics in shell-and-tube heat exchanger design such as. When the heat exchanger tube contains high pressure gas and is in a liquid-filled shell eg gas coolers in cooling water systems the problem is greater than with.

This is specific to ones design and is not engineering advice. When designing a STHE the relative pressures should be considered with the knowledge that a relief system must be designed for tube rupture in addition to other potential overpressure cases. I have a case in which i have one hot liquid.

I have a Shell Tube Heat Exchanger running to the following design pressure conditions. 1 or 2 applies. The pressure differential is affected by fluid flow rates pipe surface friction number of heat exchanger passes bulk density and viscosity.

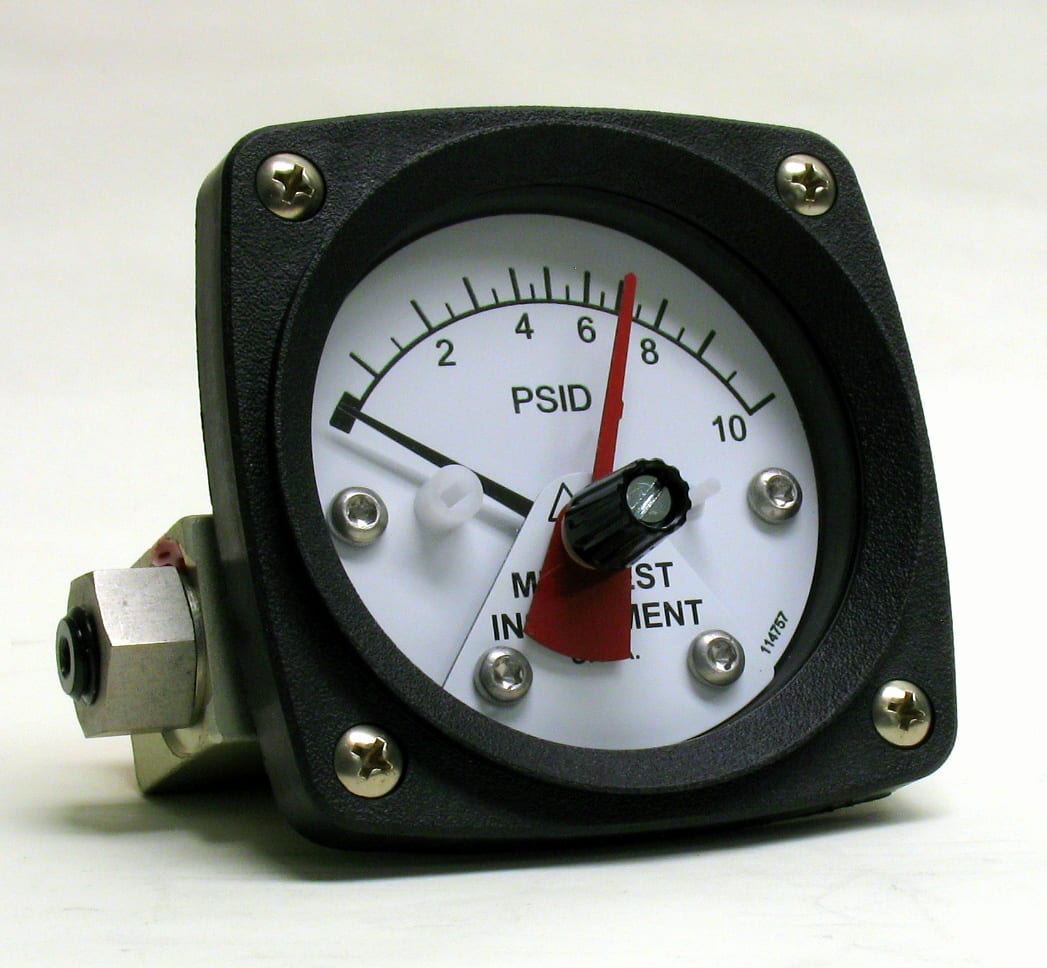

Lectures 19 Applied Heat Transfer CM3110 1232019 3 T outer bulk temperature T inner bulk temperature L BUT. Suppose we encounter a differential pressure transmitter used to measure the pressure drop across a heat exchanger. What is Differential Pressure in a Heat Exchanger.

The plate heat exchangers design pressure is defined in the Clause 73 of API 662 Part 1 Ed. Measuring differential pressure is a simple matter of comparing two separate pressure sources and noting the difference between them. And mean temperature difference.

However drawing does not call for hydro test and shell side has been designed for full vacuum. Effects of heat exchanger operating pressure. Hello Everyone i want to know what is the maximum differential pressure for which i can design a heat exchange.

Differential pressure is calculated by subtracting one of these values. For Eg If Shell side Pressure is 100 bar gauge and Tube side is 165 bar gauge for what differential pressue shall tubesheet be designed. Delta P ΔP pressure difference or differential pressure usually refers in the technical world to the drop of pressure in a piping system a heat exchanger or another machine where a liquid is passing through.

The delta symbol Δ is the fourth letter in the Greek and the Coptic alphabet. Here we focus on the application of these correlations for the optimum de-sign of heat exchangers. The heat exchanger during maintenance.

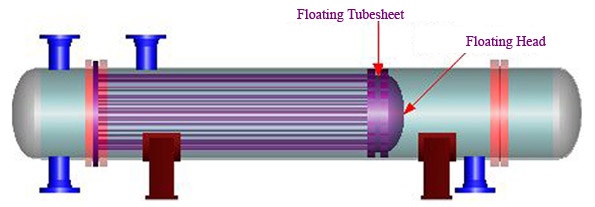

This differential-pressure-design heat exchanger 10A is a differential-pressure-design shell-and-tube heat exchanger that is made by housing a. A shell-and-tube heat exchanger with a differential pressure design type that houses multiple heat transfer tubes in the fuselage The pressure difference P 2-P 1 or P 1-P 2 between the. When i say differential pressure i mean the difference in pressure of shall side and tube side fluid.

T1 T2 T1 T2 x The Simplest Heat Exchanger. And shellside pressure drop. The differential pressure pressure under design flow conditions can be anything below the design pressure and is something the designer controls.

2006 refer exerpt below. Additional project tasks included building a hot air-to. Differential pressure is discoverable using various instruments of measurement and describes the diversity of pressure between two points.

The pressure differential between the suction and discharge of each fluid stream is the main driving force of that stream. Heat exchanger tube side pressure drop calculation Calculate the tube side pressure drop for the following heat exchanger specification Process fluid water Inlet pressure 4 barg Inlet temperature 50 0 C Outlet temperature 30 0 C Tubeside flowrate 50000 kghr Number of tubes 25 Tube ID internal diameter 1 inch Tube length 35 m. I have seen DPs of 50 psig on high temperature hot water systems but DPs of 50 to 150 psig are common.

That is their construction. The basic equa-tions for tubeside and shellside heat transfer and pressure drop are well-known. The projects main purpose was to design build and test a compact heat exchanger for supercritical carbon dioxide sCO 2 power cycle recuperators.

The choice of shell and tube type is determined chiefly by factors such as the need for the provision for differential movement between shell and tubes the design pressure the design temperature and the fouling nature of the fluids rather than the function. QT U AFLMTD 21 where QT is the total heat load to be transferred U is the overall heat transfer coefficient referred to the area A A is any convenient heat transfer area LMTD is the logarithmic mean temperature difference for the purely countercurrent flow configuration and F is the configuration. Ad Quality Plate Heat Exchangers For All Industrial Applications.

At 2200 psig on tube side and 220 psig at shell side. For example if pipe A flows at 100 psi and pipe B flows at 30 psi the differential. Can any one guide while designing any component for differential pressure say a Tubesheet in a shell and tube typ heat exchanger what is basic for considering the Differential design Pressure.

Under ASME rules if the operating pressure is higher than 15 psig then the heat exchanger is considered a pressure vessel and the pressure-vessel design code ASME section VIII Div. The typical pressure on the upstream side of this heat exchanger is 1000 PSI while the typical pressure on the downstream side of this exchanger is 970 PSI. The compact recuperator is required to operate at high temperature and high pressure differentials 169 bar 2500 psi between streams of sCO 2.

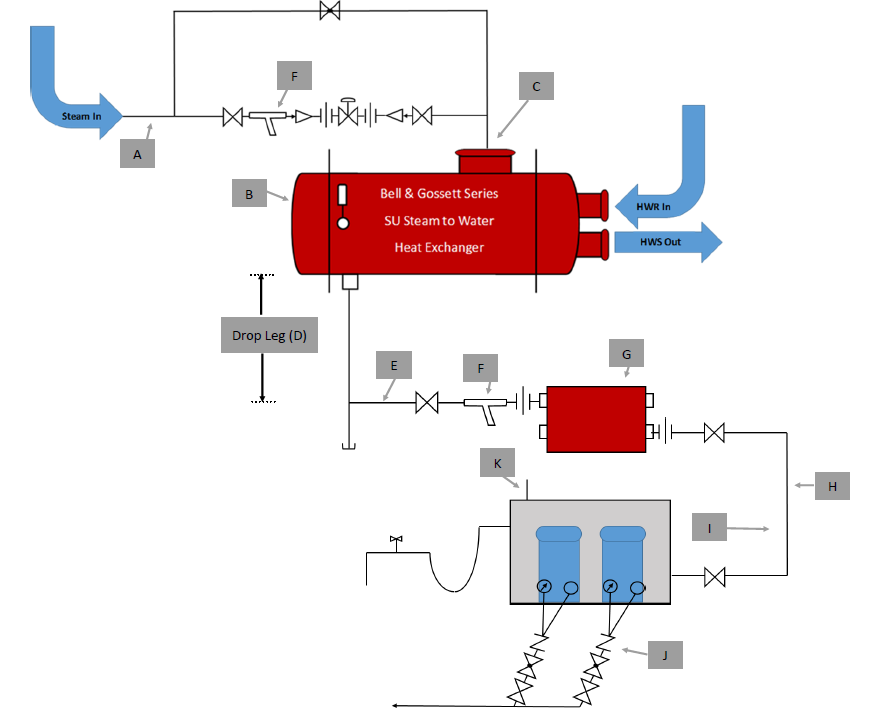

DoublePipe Heat exchanger counter current cold less cold less hot hot. The transmitter connects to this heat exchanger via a three-valve manifold. What is Differential Pressure in a Heat Exchanger.

The temperature difference between the fluid and the wall varies along the length of the heat exchanger. Similar logic applies to different pressure vessel. Differential pressure represents the difference in pressure between two points.

Design pressure Pump shut off head normal operating pressure of suction vessel head between the tangential line of the suction vessel and the centerline of the pump impeller. Then the basic design equation becomes. Maximum Differential Pressure In A Shell And Tube Heat Exchanger - posted in Process Heat Transfer.

Unless otherwise specified or approved by the purchaser the plate-and-frame heat exchanger shall be designed for design pressure on either side with atmospheric pressure or if specified vacuum on the other side.

Mechanical Design Of Heat Exchangers

Heat Exchangers Design Analysis

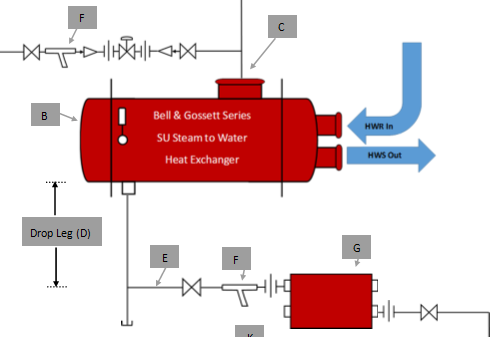

Understanding Steam And Steam Heat Exchangers Part 1

Steam Trap Operation Steam And Steam Heat Exchanger Basics Part 8

Heat Exchanger Differential Pressure Transmitter Instrumentationtools

Measuring Impact Of Heat Exchanger On Differential Pressure Performance Mid West Instrument

0 comments

Post a Comment